Apiar are revolutionising the world of horology one layer at a time using innovative additive manufacturing that is paired with sustainable British engineering.

Additive Manufacturing, commonly known as metal 3D printing, has recently undergone major advances in terms of both precision and cost, thus allowing it to now be available to the consumer market. Apiar utilises aerospace standard Grade 23 Titanium, superior to the Grade 5 more commonly used in watchmaking. Its premium qualities make it ideal for aerospace, biomedical applications and of course superior quality watch cases. This results in extreme comfort on the wrist and until you look down, a pleasant surprise that you have a great looking watch there.

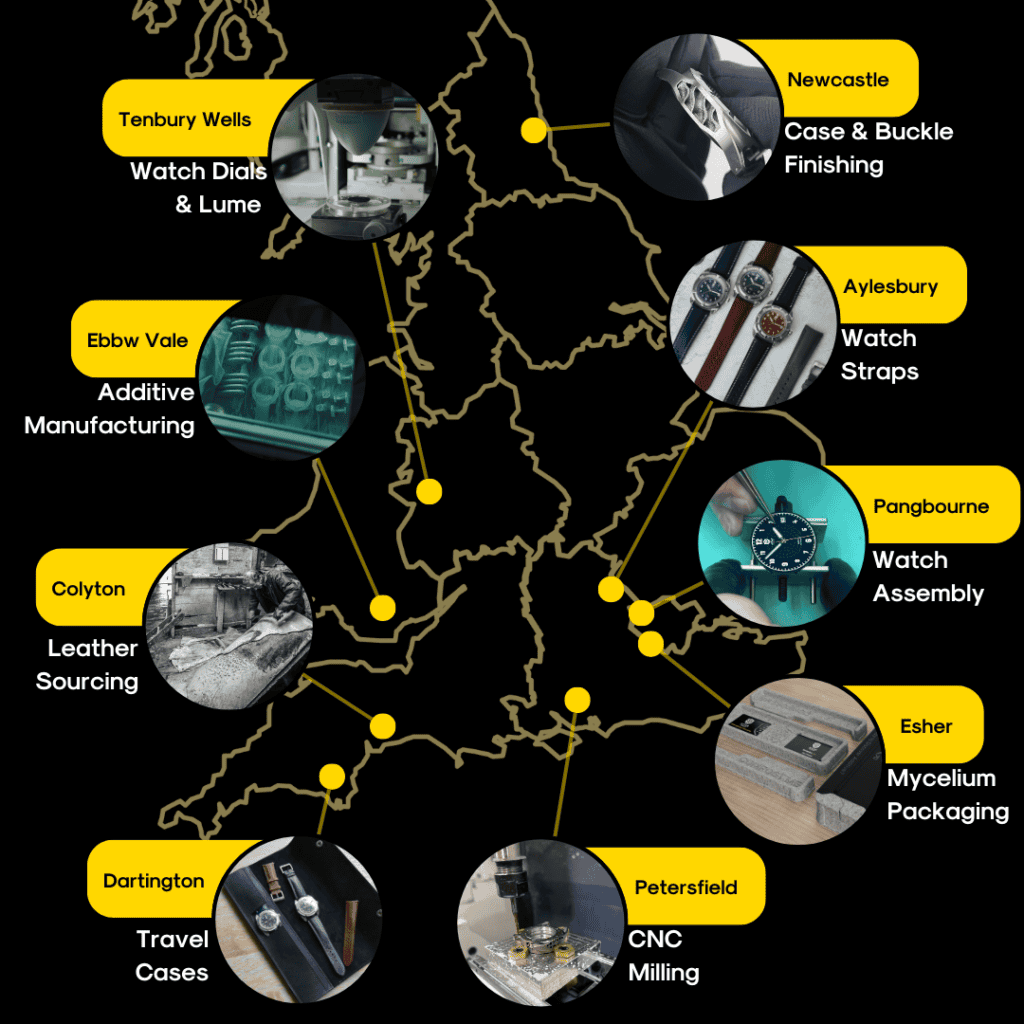

Celebrating Made In The UK

Apiar have a network of companies across the United Kingdom they rely on to produce the Invenire v1.0. They range from Apex Additive Technologies who manufacture the titanium cases in Ebbw Vale to Tanner Bates who make the sumptuous leather watch cases in Dartington, up to Newcastle where The Watch Toolkit finish the cases and strap buckles.

The straps are handcrafted and bespoke made from sustainable sourced leather, suede, and TPU by The Strap Tailor in Aylesbury with the leather sourced by J&FJ Baker. The watches are assembled in Berkshire by Horologium, a workshop founded by Raphael Pfund and Raquel Palmieri. Packaging and shipping is undertaken by the Magical Mushroom Company which use natural elements and offer ‘planet positive’ packaging solutions.

Apiar Invenire v1.0 On The Wrist

Every Invenire v1.0 can be custom manufactured according to individual configurations and uniquely numbered – this is achieved using the configurator on their website. The Grade 23 Titanium case comes in three different ‘lattice’ designs, namely, Honeycomb, Gyroid and X-Lattice. The watch I’m wearing has the Gyroid design which is a very complex geometry that is excellent at handling compressive loads.

The dial on this watch has the ‘hexagon’ design which adds depth and is made by Bedford Dials, crafted since 1840, these dials feature intricate guilloché, hand-painting, and precise pad printing, reflecting individual design. They embody Apiar’s dedication to British engineering. You can choose either Roman or Arabic numerals for the dial, which also has a date window at 3 o’clock.

Inside the Invenire v1.0 is the Swiss Made Movement – La Joux-Perret G100. La Joux-Perret is a well established Swiss movement manufacturer, who have been working with many of Switzerland’s most prestigious brands for many years. The watch is water resistant to 10 ATM (100m).

Overall, the Invenire v1.0 is an excellent timepiece which has several fascinating elements and can be customised to the prospective owner’s specifications. There will only be 160 made. Depending on your specifications will cost £2,160 (incl. VAT) and would be a great addition to any collection.

Technical Specifications:

Model Reference: Invenire v1.0

Invenire Case

– Grade 23 Titanium, a Ti6Al4V alloy with lower amounts of oxygen and iron compared to the standard Grade 2 or 5. Ti64 alloy. The material is well-known for having excellent mechanical properties: low density with high strength and excellent corrosion resistance.

– 39mm case diameter, skeletonised with latticed interior, 12.55mm depth and 47mm lug-to-lug.

– 100m (10ATM) water resistance.

– Made in the UK (3D printed in Wales and machined in England).

Dial

– 5 hand-painted matte colours: black, onyx grey, engineering orange, oxford blue and racing green.

– CNC machined from a single brass billet.

– 4 machined central sunken guilloche patterns: Clous de Paris, Hexagon, Striations and Blank.

– Date window at 3 o’clock.

– Tritec Swiss Super-Luminova YL C1 white printed minute track.

– Roman and Arabic numerals.

– Made in the UK

Leather Strap

– Hand crafted leather and suede straps.

– Black and Brown leather options sourced from oak tannery in Devon.

– Blue Epsom leather, Grey Epsom leather and Grey / Olive suede sourced from Italy.

– Made in the UK

TPU Strap

– Additively Manufactured from 90A TPU.

– Configurable design to match case lattice or plain.

– Waterproof and hard-wearing.

– Made in the UK

Travel Case

– Black leather travel case lined with black pig suede.

– Leather and suede sourced from local oak tannery in Devon.

– Hides are sourced from the local meat industry.

– Handmade by artisans in Devon.

– Made in the UK

Movement

– La Joux-Perret G100 version soignée vis bleues.

– Power Reserve: 68 Hours

– Jewels: 24

– Type: Automatic

– Made in Switzerland

– Modified and Regulated in the UK

Crystals

– Domed front: Sternkreuz domed sapphire crystal with AR coating on the inside.

– Exhibition back: Sternkreuz sapphire crystal.

– Made in Germany

Hands

– Relumed Hands (Tritec Swiss Super-Luminova YL C1 white)

– Made in Switzerland / Relumed in the UK

Crown

– Screw down Crown

– Made in Italy / Engraved in the UK

Serial Numbered Individually numbered, sequentially based on the number of orders for that particular configuration.

Retail Price Price based on configuration: Starting at £2160 (Inc. VAT) £1800 (Ex. Vat)

For more information please visit APIAR