Watch Supply started a few years ago as a small watchmaking company to assemble watches in their London workshop, today known as Fink Watch Manufacturing.

The concept was simple, create interesting watches and assemble them in their workshop, ensuring quality work at fair prices. After a while, they had another idea: Why not also offer watch enthusiasts the chance to complete the assembly at home and build their own automatic watch, benefitting from their knowledge and development of parts.

Watch Supply offer an exceptional experience at home or in their workshop in London, where every watch enthusiast can now build their own automatic watch with their starter kits. They are designed to be assembled without any prior knowledge and contain all the tools and parts needed to complete the project within 2-3 hours.

In addition to their kits, they also offer a unique live experience in their workshop in London. It is an opportunity to take a seat at a watchmaker bench, learn about mechanical movements and assemble your own watch in a small group of like-minded watch enthusiasts.

I was invited to their workshop in London for one of their ‘watchmaking live’ events to build my own automatic watch. From the outset, it was a brilliant experience, being in an environment with fellow collectors and those with a shared interest in horology. I was greeted by Felix Finkler, Co-Founder (below) who gave me a tour of the workshop as we waited for the others to arrive.

When everyone was there, we spent time choosing our watches and the individual elements that would form the build of the watches. There are several models to choose from including, Divers, Pilot and Tool watches. Each have a myriad of dial colours, hands, cases and strap options (below).

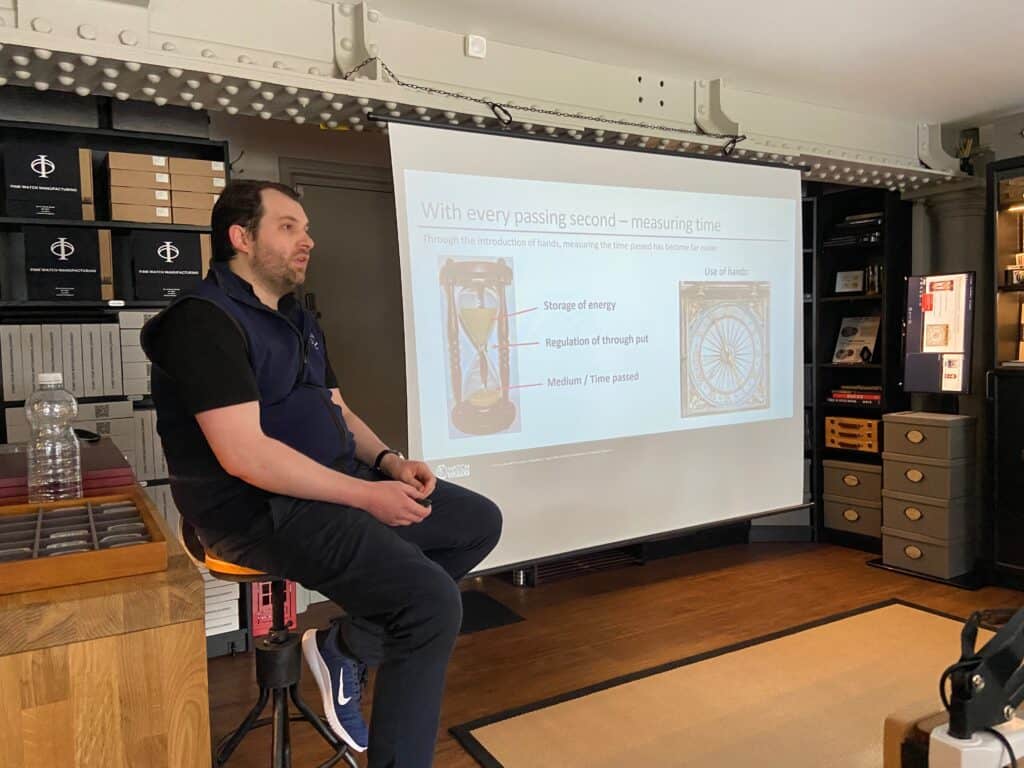

Once we had chosen our watches, Felix gave us a presentation about movements and British watchmaking. The excellent presentation went through hundreds of years of watchmaking history, and explored how we arrived at the modern watch movement starting from a simple sand-clock or hourglass.

After the introduction, the group had a greater understanding on how mechanical movements worked and with great excitement, this was the time to start the assembling our own watches. Everything we needed including tools, components and instructions to build a watch and to take it home with you was supplied.

The seminar included their full watchmaking tool kit which allowed us to assemble our watches during the seminar. The kit has been specifically designed for the watchmaking event and contained all the tools needed. They are also designed to be used at home, should you wish to order a watchmaking kit online.

There was a very positive feeling in the workshop and we all started by getting familiar with the tools we’d need to complete the build. Each watchmaking bench has it’s own screen with a tutorial video that took us through the process step-by-step. This was excellent as it allowed you work at your own pace, to stop at any time and rewind if you missed anything.

The movements are already complete, so most of the time was spent on placing the dial, lining up the date window, checking the setting and putting on the three the hands (four, if it’s a GMT watch). Both Felix and Chris were on hand to help if it was required.

My watch of choice was the Bronze Diver (above) with cyclops crystal, which was their first kit with a bronze case made of a strengthened copper alloy with 8% tin, commonly known as CuSn8. Over time the case will change its colour and develop a beautiful and unique patina. The case is completed by a unidirectional 120-click bezel with a matte insert and a screw down crown to ensure the water resistance.

The kit features a matte black dial with a polished, gold coloured hour markers and matching luminous filled diver hands matching the warm hue of the bronze case. Underneath the dial, the reliable NH-35A automatic watch movement will ensure precise time keeping.

It was a thoroughly enjoyable experience at the Watch Supply workshop and it felt great and very satisfying to create and build my own watch. This is a good introduction to watchmaking and showcases the skills required to become a watchmaker. It was good to be in an environment where we could learn about the workings of the watch movements and history of timekeeping. There was a Father and Son at the session, which was great to see and hopefully this will be a place to inspire people to want to know more about the wonderful craft of watchmaking.

There is something very satisfying when you look down at a watch that you have built yourself.

For more information please visit Watch Supply